I'm a data scientist at ASML specializing in manufacturing analytics and industrial AI. I build ML-powered tools, process mining dashboards, and intelligent automation to optimize factory operations, reduce waste, and accelerate decision-making. From predictive maintenance to process optimization, my work bridges data and strategy to drive measurable impact across engineering, operations, and finance.

Jan '23 - Present

• Secured approval for the first data scientist role in the manufacturing organization by outlining a strategic AI/ML vision and showcasing proof-of-concept use cases.

• Implemented an XGBoost regression model and A* search algorithm to streamline the high-speed lens polishing process, accelerating convergence from raw blanks to qualified optical components, saving a total cycle time value of ~$350K/year.

• Led development of foundational data products in sensor integration and equipment effectiveness, enabling predictive maintenance, real-time alerting, and KPI tracking (e.g., mean-time-to-failure, mean-time-between-failure, utilization rate).

• Established process mining infrastructure from scratch, building SQL-based pipelines and Celonis dashboards to surface friction points and drive improvements across manufacturing, logistics, and finance.

• Reduced scrap cycle time by 2 weeks and material holding cost of ~$500K by mapping ownership across the scrap process and automating milestone reminders using custom workflows.

• Segmented product families with K-means clustering and statistical profiling, enabling planners to incorporate historical variability into release strategies and buffer calculations.

• Served as cross-functional thought partner to senior leadership, defining technical requirements for analytics solutions, while actively participating in the DS/ML community of practice to elevate site-wide analytics standards and knowledge sharing.

July '22 - September '22

• Conducted over 100 hours of time studies and established new baseline for labor hours across

3 work centers to support future capacity planning and move rate targets.

• Identified over 20 process improvement opportunities and procedural errors, contributing to

annual cycle and labor time reduction goals.

• Implemented new compilation process of 2148-image datasets using MatLab to assist with defect

inspection and reduced total cycle time by over 50%.

• Assisted Production Engineers with ad-hoc data analyses to support decision making.

May '18 - April '20

Strategic Sourcing Initiative

• Lead engineer responsible for the validation and implementation of over 500 newly-sourced steel,

hydraulic, and electrical components covering 3 major product lines, contributing to the

realization upwards of $4M in cost savings.

• Took initiative to manage project timelines across 5 facilities as the Global Pump Validation

Lead and minimized duplication of work and unnecessary allocation of resources, thereby

implementing new products ahead of schedule and resulting in an additional upwards of $100K

in cost savings.

• Supported implementation of lean business practices through production life cycle and

supply chain.

Data Analytics & Process Improvements

• Designed model to predict price of new parts using several disparate data sets across engineering

and global supply chain, increasing price prediction accuracy from 70% to 94%.

• Created an automated machine weight data entry, cleaning, analysis, and storage pipeline based

on customer feedback, ensuring quality of assembled machines and serial label information,

and improving brand perception.

• Developed and implemented a web-based tool (Flask) that queries BOM data directly from ERP

and presents differences in a user-friendly and exportable format, reducing task time by 100%.

• Created Python scripts to automate SQL queries, report generation, and file transfers to

reduce SG&A.

September '16 - March '18

• Managed a 6-member team and project timelines, with a 3rd place overall finish at

national competition.

• Executed top-level design decisions around the electric drivetrain system such as purchasing,

packaging, and manufacturing.

• Justified optimal gear reduction of the car based on simulation results of the

competition drive course.

• Established sponsor relations with local businesses and received over $10K in

value of services and donations.

• Redesigned and manufactured eCar motor mounts and gearbox mounts to

improve packaging, and serviceability.

September '21 - December '22

Courses:

• Probability & Statistics

• Optimization

• Simulation

• Data Analytics

• Analytics on the Cloud

• Supply Chain

• Transportation & Logistics

• Machine Learning

• Deep Learning

September '20 - March '21

Courses:

• Java Programming II

• Intro to Software Development

• Database Development

• SQL

September '13 - March '18

Courses:

• Java Programming I

• Scientific Computing

• Scientific Computing

• Composite Design

• Manufacturing Technology

July '16 - September '16

• Minimum of 200 hours of shop experience.

• Familiarization of programming and operation of CNC machines.

• Fabricated parts such as vise stops, tap guides, parallel clamps and a personal project, a shift knob.

October '24

• Developed an AI-driven video content creation application leveraging Google Video Intelligence and GPT-4o for video annotation, and LLMs for script and shot list generation with RAG, reducing content production time for businesses.

• Designed and implemented scalable data pipelines integrating multiple tools (Google Cloud Storage, Firebase, and Qdrant) to preprocess, annotate, and store video data, ensuring high-quality, structured datasets for analysis and AI-driven insights.

LinkedIn Post

Demo

July '23

• Automated the extraction, structuring, and enrichment of recipe PDFs using Make, ChatGPT, and Airtable, centralizing personal recipes with structured metadata.

• Enabled personalized meal recommendations and automatic grocery list generation, saving time and effort in weekly planning.

LinkedIn Post

May '22

• Constructed a discrete event simulation model of NYPD dispatch using historical crime and response data,

providing means to analyze efficiency of current system.

• Optimized number of vehicles needed per precinct based on response time.

• Proposed different working and back-up policies across precincts to further decrease response time to

emergency calls by 69% without increasing number of vehicles.

Presentation

December '21

• Data-mined NFT collection (Cryptopunks) attributes, transaction, and market data from disparate data sources.

• Utilized KNN to group similar tokens together, thereby determining the inherent price and rarity of clusters.

• Constructed a logistic regression model to predict whether specific clusters will increase in price in the future.

Presentation

March '21

• Tracks related to the genres of Trap and Dubstep were gathered by scraping five popular

music-discovering channels on YouTube.

• Audio features data was tied to those that could be found in Spotify’s library.

• Constructed and hosted an interactive dashboard through Dash Plotly with a Postgresql backend.

Link to Hosted Dashboard

Github Repository

May '20

• Scraped posts submitted to the r/Trap subreddit, an online community where users

share Trap music, and discuss the genre.

• Cleaned and organized music-related posts by artist and track names, thereby determining

the most popular artists by the number of votes users gave to each artist.

• Created an animated bar chart, visualizing the total number of votes each artist gained

over an 8 year period.

Github Repository

Reddit Post

December '17 - March '18

• Wrote a MatLab script that utilizes Classical Laminate Theory to predict laminate and

sandwich panel deflection under 3-point bend loading to within 10% of testing results

• Conducted tests to prove structural equivalency of the box while decreasing overall weight by 13% from previous aluminium design

Mechanical Design

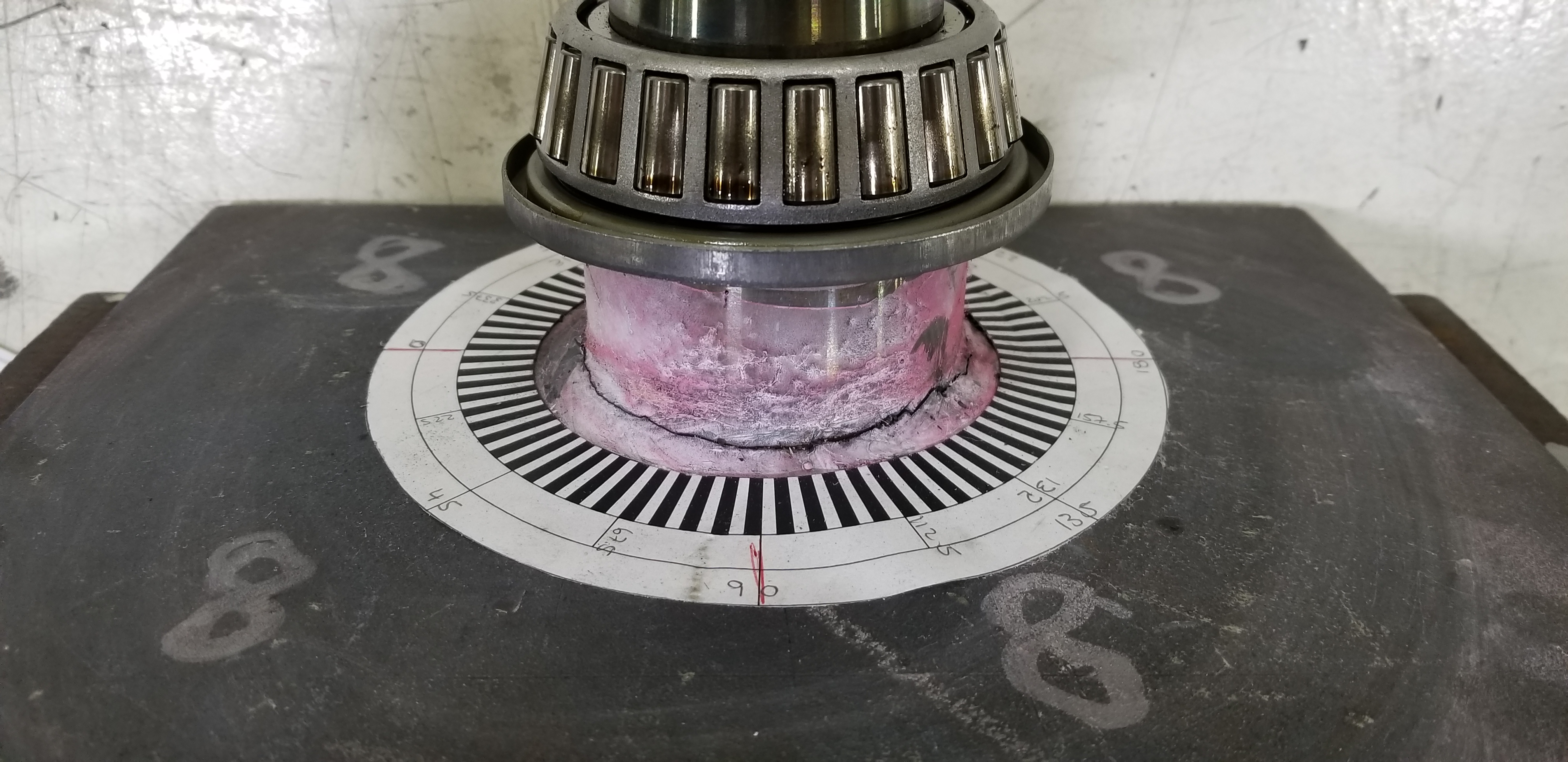

Improvements from T28:

• In-line motor and gearbox mounting with increased overall stiffness, ensuring concentricity of power transfer components.

• New mounting design also allowed for ease of installation and service. Previous design had poor chassis jigging and also required heavy motors to be removed if gearboxes needed to be serviced.

• Outboard gearboxes not only allowed for better serviceability but also for a smaller and lighter chassis and more aggressive undertray.

• Long lead time out-of-house processes was required for half-shafts but delays were minimized by avoiding major redesigns.

• Validation of CV boot material was done through tensile tests. Correct selection of material resulted in better lubricant retention during drives.